Choosing the wrongprinting methodcan result in faded designs, high costs, and missed deadlines. This decision is crucial for ensuring your project’s success, whether it’s for business merchandise, promotional materials, orcustom apparel.

The confusion often lies in choosing between the two main printing options: screen printing and digital printing. Many people wonder about the differences between these methods.

Screen printing applies each color individually, making it great for simple designs but potentially time-consuming. Digital printing, however, produces vibrant, multi-color designs in a single pass, making it ideal for complex images. Confused about which to choose? Don’t worry.

We’ll break down the difference between screen printing and digital printing and also the pros and cons of each method, helping you make an informed decision that suits your project’s needs and budget. Let’s ensure your prints come out perfect every time.

- What is screen printing?

- Advantages of screen printing

- Drawback of screen printing

- What is screen printing best used for?

- What is digital printing?

- Advantages of digital printing

- Drawbacks of digital printing

- What is digital printing best used for?

- Screen printing vs digital printing – what’s the difference?

What is screen printing?

Screen printinginvolves creating a stencil, known as a “screen,” and using it to apply layers of ink onto the printing surface. Each color requires a separate stencil, applied one at a time and layered to achieve the final design.

This method is highly versatile, and suitable for printing on various materials such as textiles, plastic, and latex. Screen printing has a long history and remains widely used due to its effectiveness and adaptability. While technology has advanced to speed up the process, the fundamental technique of pushing ink through a stenciled screen remains unchanged.

Advantages of screen printing

Screen printing offers several practical advantages that make it popular for various printing needs:

Specialist inks: It supports a range of specialized inks like foil, glitter, and fluorescent, allowing for unique textures and effects in designs. It primarily uses Plastisol and water-based inks known for their vibrant colors.

Color vibrancy: Screen printing achieves vivid colors that are visually striking and noticeable. Printers can easily match specific colors using the Pantone Matching System, ensuring consistency in branding.

Custom color matching: Inks can be mixed to match exact Pantone colors accurately, maintaining uniformity in design and brand identity.

Durability: Screen prints are durable and resistant to fading over time, making them suitable for long-term use.

Versatility: It can be used on a variety of fabrics and substrates, providing flexibility in printing on different materials.

Drawback of screen printing

- Limited color options due to separate stencils for each color.

- Costlier for small print runs due to setup costs.

- Prints can have a noticeable texture.

- Potential for higher material wastage.

- Difficulty achieving smooth color blends.

What is screen printing best used for?

Screen printing is best used for:

What is digital printing?

Digital printing is a modern process where your artwork is processed digitally and directly printed onto your product’s surface. Unlike methods like heat transfer or appliqué, digital printing applies ink directly to the fabric of your shirt. It’s known for its ability to handle intricate designs and is versatile enough to print on various surfaces.

In the print industry, “digital printing” refers to using specialized inkjet printers that can print textile inks. These printers convert digital images into printable formats, making them suitable for a wide range of applications.

Digital printing, also known as Direct to Garment (DTG) printing in the screen printing world, has become popular for its capability to reproduce detailed designs with precision and vibrant colors.

Advantages of digital printing

Digital printing offers several advantages over traditional methods like screen printing:

- Detail: Ideal for designs with detailed patterns or photographs, digital printing ensures precise and clear prints without compromising on quality.

- Color blending: It excels in reproducing smooth color transitions, making it suitable for designs that require accurate color combinations.

- Consistency: Digital printing provides uniformity in prints across all pieces since the process is computer-controlled, ensuring consistent ink distribution and color accuracy.

- Quantity flexibility: It’s efficient for smaller print runs like 50 or less.

Drawbacks of digital printing

Digital printing has its limitations and drawbacks:

- Limited fabric compatibility, as it’s suitable only for specific types.

- Color vibrancy is not as strong as screen printing.

- Unable to match Pantone colors precisely.

- Colors may fade over time with washing and use.

What is digital printing best used for?

Digital press printing is best used for:

- Custom apparel like t-shirts, hoodies, and jerseys.

- Promotional productssuch as tote bags and hats.

- Marketing materialslike posters, flyers, and brochures.

- Fine art prints for detailed artworks and photographs

Screen printing vs digital printing – what’s the difference?

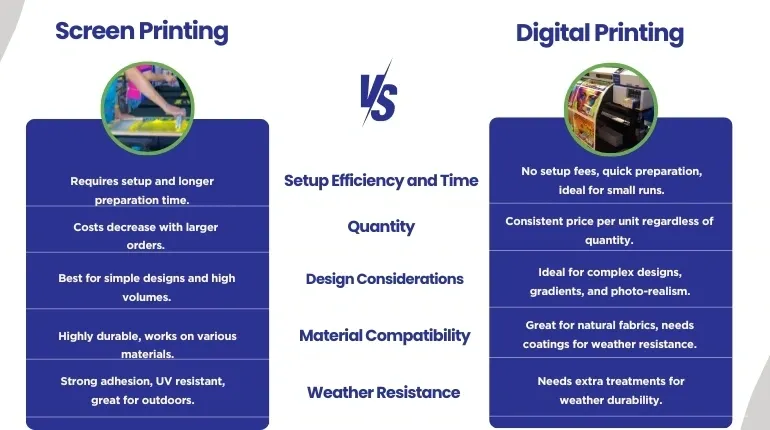

Choosing the best method depends on what you plan to print and the surface. Digital printing delivers a sharp, detailed print, whereas screen printing offers a softer, vintage appearance. Because each method excels in different ways, here are a few factors to consider before making your decision.

- Comparing costs: Screen printing is cost-effective for large quantities due to faster printing speeds, averaging $5 to $10 per unit. Digital printing, with minimal setup fees, suits smaller orders at $1 to $4 per unit.

- Setup efficiency and time: Screen printing involves setup fees ($20 to $50 per color) and about 10 minutes per job. Digital printing requires no setup fees and less preparation time, ideal for smaller runs.

- Price per print and quantity: Screen printing costs decrease with larger orders, while digital printing maintains a consistent price per unit regardless of quantity.

- Design considerations: Screen printing suits simple designs and high volumes, while digital printing excels with complex designs, gradients, and photo-realistic images.

- Durability and material compatibility: Screen printing offers superior durability and works on diverse materials. Digital printing is best for natural fabrics like cotton and requires additional coatings for weather resistance.

- Adhesion and weather resistance: Screen printing provides strong adhesion and UV resistance, ideal for outdoor use. Digital prints may require additional treatments for weather durability.

Conclusion

So there you have it. Our guide provides insight into the processes and results achievable with screen printing and digital printing. There are various factors to weigh when choosing between these methods. At Print to Brand, we provide professional printing services for a wide array of customizable products.

Answering your questions

The cost of screen printing versus digital printing depends on the order size and design complexity. Screen printing typically has higher setup costs, making it more expensive for small orders. However, for larger quantities, the cost per unit decreases significantly, potentially making it cheaper than digital printing for bulk orders.

Yes, digital printing does last on shirts, especially with proper care. Advances in technology and inks have improved the durability and wash-fastness of digitally printed garments. While it may not match the lifespan of traditional screen printing, a digitally printed shirt can maintain vibrancy and detail through numerous washes.

Screen printing excels in vibrant, opaque colors and is versatile across various materials and fabric types. It’s ideal for designs needing high vibrancy or special ink effects. Digital printing, on the other hand, is superior in reproducing intricate details and a wide color range, making it suitable for complex or photorealistic designs.

Screen printing works best for large orders and designs that need solid colors. However, it can be costly for smaller batches and may create thicker designs. Digital printing is ideal for detailed, multi-colored designs of any quantity. It offers consistent pricing and produces lightweight, breathable prints.

Digital printing tends to be less durable compared to screen printing. This is because it uses thinner layers of ink that may not perfectly match the material’s color or texture, leading to potential issues with contrast and longevity. When choosing between printing methods, consider your budget, desired print quality, and how long you need the prints to last.