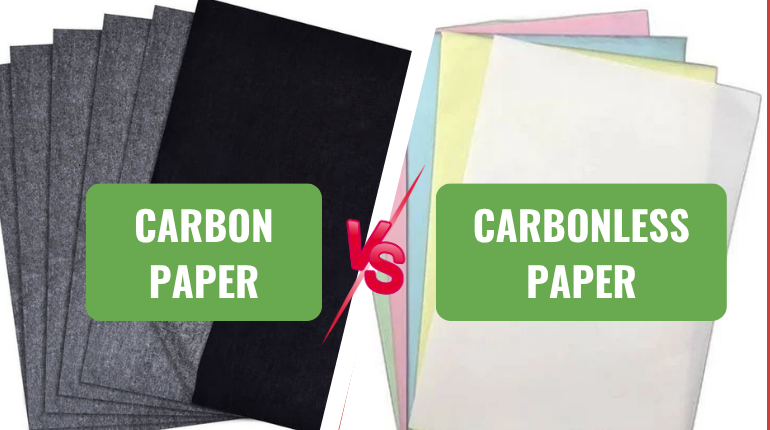

In every business, duplicate documents, invoices, and receipts ensure accuracy and professionalism. Choosing the right paper directly impacts document quality and workflow efficiency. Carbon paper and carbonless paper (NCR forms) both create copies, but they work in different ways. Carbon paper transfers writing using an ink-coated sheet, while carbonless paper produces duplicates through pressure-sensitive micro-encapsulated coatings.

In this article, you will find out the key differences, advantages, and practical uses of carbon and carbonless paper. You will also learn how businesses in retail, logistics, and administration can select the type that fits their workflow, reduces errors, and saves time and cost.

Key Takeaways

- Carbonless paper, also called NCR (No Carbon Required) paper, is a modern alternative to traditional carbon paper that creates instant, multi-copy duplicates using micro-encapsulated dye and reactive clay, eliminating the need for messy carbon sheets.

- Carbonless paper ensures clean, uniform, and durable copies, improving efficiency and professionalism in high-volume operations across retail, logistics, healthcare, and administrative sectors.

- While carbon paper is cheaper and suitable for occasional, low-volume duplication, NCR paper is ideal for businesses that require speed, accuracy, eco-friendliness, and multiple verified copies for invoices, receipts, and contracts.

What is Carbon Copy Paper?

Carbon paper is a thin sheet coated with pigmented or ink-based material that transfers writing or typing impressions onto a sheet placed underneath.

When pressure is applied by a pen, typewriter, or printer, the ink from the carbon-coated side transfers to the next sheet, creating an exact duplicate of the original content.

Common Uses:

- Business Forms:Invoices, receipts, and multi-part forms often rely on carbon paper to create duplicates.

- Legal and Administrative Documents:Agreements, contracts, and official forms use carbon paper to maintain multiple copies simultaneously.

- Art and Craft Applications:Artists sometimes use carbon paper to trace designs or patterns.

Advantages:Low cost, easy to use, suitable for manual duplication.

Disadvantages:Messy, prone to smudges, requires separate sheets.

What is Carbonless Paper?

Carbonless paper, also known as NCR (No Carbon Required) paper, creates duplicate copies without using a separate ink-coated sheet.

Each sheet of carbonless paper has a special micro-encapsulated coating or clay layer. When pressure is applied by writing or printing, the capsules break and react with the coating on the sheet below, forming a visible duplicate. This allows multiple copies to be produced simultaneously.

Common Uses:

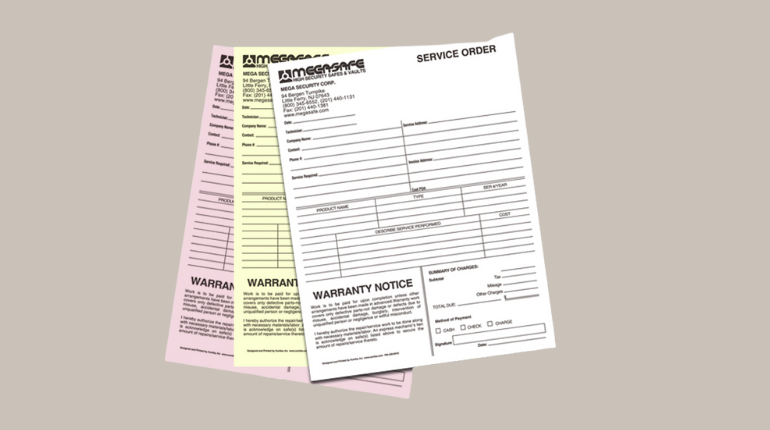

- Invoices and Receipts:Businesses in retail, logistics, and service industries often use carbonless paper for professional, multi-part receipts.

- Legal and Administrative Forms:Contracts, agreements, and government forms frequently rely on NCR sheets for accurate, legible copies.

- Healthcare and Education:Patient records, school forms, and admission documents use carbonless paper to maintain multiple records.

Advantages:Clean copies, time-saving, eco-friendly.

Disadvantages:Higher cost, sensitive to pressure, shorter shelf life.

What Are the Differences Between Carbon Paper and Carbonless Paper?

Both carbon and carbonless paper serve the same purpose — to produce duplicate copies of written or printed documents — but they differ completely in structure, composition, and technology.

1. Composition and Structure

Carbon Paper:Carbon paper is a thin sheet coated on one side with a dry ink or pigment layer, usually made from wax, graphite, or carbon black. When placed between two sheets, pressure from writing or typing transfers this pigment onto the bottom sheet.

Carbonless Paper (NCR Paper):Carbonless paper uses micro-encapsulation technology. Each sheet contains microscopic dye capsules on the back and a reactive clay coating on the front. When pressure is applied, these capsules burst and react with the clay, forming a clear, permanent image on the next sheet without using a separate carbon layer.

2. Copying Mechanism

Carbon Paper:The copy depends on physical pressure. Every stroke transfers ink from the carbon layer to the sheet below. The copy strength depends on the writing pressure and can sometimes appear uneven.

Carbonless Paper:The duplication happens through a controlled chemical reaction between encapsulated dyes and a clay developer. This ensures clean, uniform copies even with light writing pressure.

3. Number of Copies

Carbon Paper:Typically used for one duplicate per sheet. Multiple layers can reduce print quality because the ink transfer weakens through layers.

Carbonless Paper:

Allows for two-part, three-part, or even five-part forms (for example: white–yellow–pink–green–blue), making it ideal for invoices, receipts, and order forms requiring multiple copies.

4. Cleanliness and Handling

Carbon Paper:Handling carbon paper can be messy. Ink residue easily transfers to hands, documents, and surfaces. Over time, stored carbon sheets may smudge or deteriorate.

Carbonless Paper:The encapsulated dyes remain sealed until activated, making it completely clean to handle. There’s no loose ink or staining, which improves overall presentation and user experience.

5. Durability and Efficiency

Carbon Paper:The coating wears off after several uses, leading to faded or incomplete copies. Sheets can tear or wrinkle easily.

Carbonless Paper:Each form set is single-use, but the resulting copies remain sharp, durable, and archival-quality, suitable for business records and official documentation.

6. Cost and Usability

Carbon Paper:Low initial cost and suitable for manual, low-volume tasks. However, it increases handling time and can slow down workflow when multiple copies are required.

Carbonless Paper:Slightly more expensive per sheet, but it improves operational efficiency in high-volume environments such as retail, logistics, healthcare, and administration.

7. Environmental Impact

Carbon Paper:Often made from non-biodegradable materials and is not easily recyclable due to its ink content.

Carbonless Paper:Designed to be eco-friendly and recyclable. It eliminates the need for separate carbon sheets and reduces paper waste.

Which One Should You Choose?

If your workflow involves creating multiple copies of invoices, receipts, or contracts every day, carbonless paper is the smarter choice. It produces instant, smudge-free duplicates without using separate sheets, saving time and maintaining a professional look. It’s also more eco-friendly since it eliminates the need for carbon sheets and reduces paper waste.

However, if you only need a few copies occasionally or prefer a low-cost option for manual duplication, carbon paper can still serve basic purposes. It’s useful for handwritten forms, receipts, or records where technology is limited or unnecessary.

In short, carbonless paper fits modern businesses that value speed, cleanliness, and sustainability, while carbon paper works best for simple, small-scale use.